This means that Luxurious Furniture Company only sold roughly a third of its inventory during the current year.

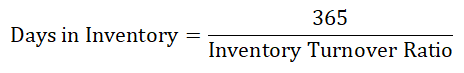

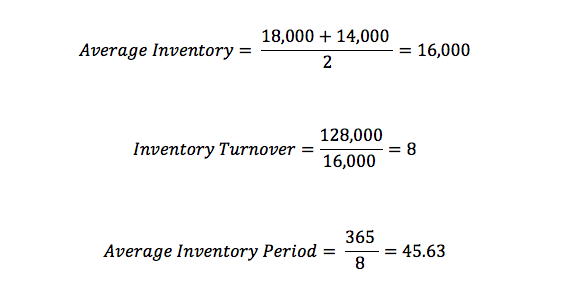

Then, we calculate Inventory Turnover Ratio using the Formula. Average Inventories = Beginning Inventories + Ending Inventories) / 2.

#Average inventory turnover formula download

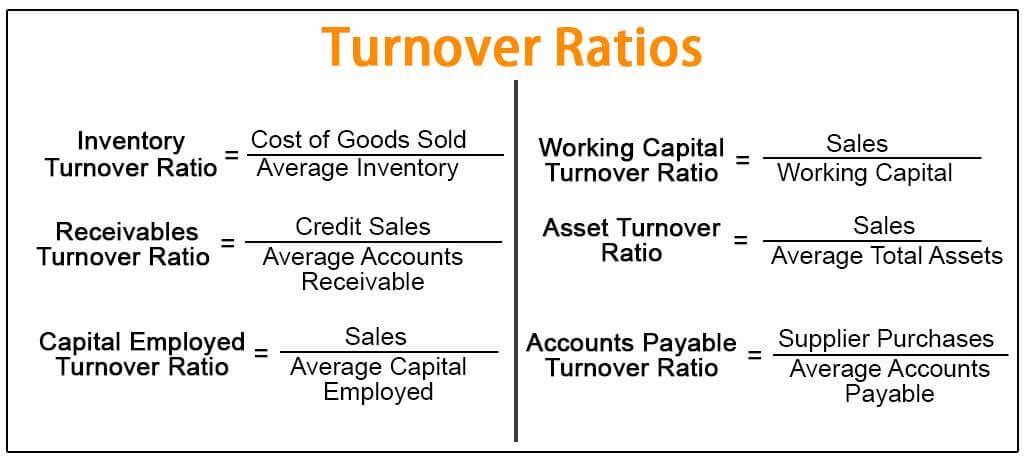

You can download this Inventory Turnover Ratio Template here – Inventory Turnover Ratio Template This enables you to measure how often the average inventory ratio is sold or turned in during a particular period. The inventory turnover ratio is a simple ratio that helps to show how effectively inventory can be managed by comparing average inventory and the cost of goods sold for a particular period.

The inventory turnover ratio is a ratio that shows how many times a company has replaced and sold inventory during a period, say one year, five years, or ten years. It shows how fast a company can replace a current period batch of inventories and transforms it into sales to find a balance that is right for your business. The inventory turnover ratio and an efficient ratio formula are important. The Inventory Turnover Ratio Formula helps you find a balance that is right for your business and will lead to making a profit in business.

#Average inventory turnover formula free

Intuit accepts no responsibility for the accuracy, legality, or content on these sites.Start Your Free Investment Banking Courseĭownload Corporate Valuation, Investment Banking, Accounting, CFA Calculator & others Inventory Turnover Ratio Formula Intuit does not endorse or approve these products and services, or the opinions of these corporations or organizations or individuals. We provide third-party links as a convenience and for informational purposes only. Readers should verify statements before relying on them. does not warrant that the material contained herein will continue to be accurate nor that it is completely free of errors when published. Accordingly, the information provided should not be relied upon as a substitute for independent research. does not have any responsibility for updating or revising any information presented herein. No assurance is given that the information is comprehensive in its coverage or that it is suitable in dealing with a customer’s particular situation.

Applicable laws may vary by state or locality. Additional information and exceptions may apply. This content is for information purposes only and should not be considered legal, accounting, or tax advice, or a substitute for obtaining such advice specific to your business. High demand, without the proper warehousing and shipping workflows in place, could lead to delays in replenishment and in deliveries all of which keep stocks on your shelves for longer.

Having high demand may seem like the most obvious way to reduce your weeks on hand but without proper inventory management, it could actually have the opposite effect. This also reduces the chances of over-ordering. Establishing inventory PARs allows you to set-and-forget your inventory ordering, with orders placed once a certain threshold for each item is reached. This measure can help determine the PAR (Periodic Automatic Replenishment) inventory level that an organization should have at all times. Weeks on hand refers to the amount of time it takes to sell the inventory on hold. Once you have this measurement, the next step is to find ways to have fewer weeks on hand and increase efficiency. So there you have it, the weeks (and days) on hand metric for your inventory. Assuming you have COGS of $5 million and your average inventory is $500,000 Īlternatively, for businesses with high, recurring demand, calculate your days of inventory on hand, simply by taking your accounting period in days (356 days) and dividing it by your inventory turnover rate:

0 kommentar(er)

0 kommentar(er)